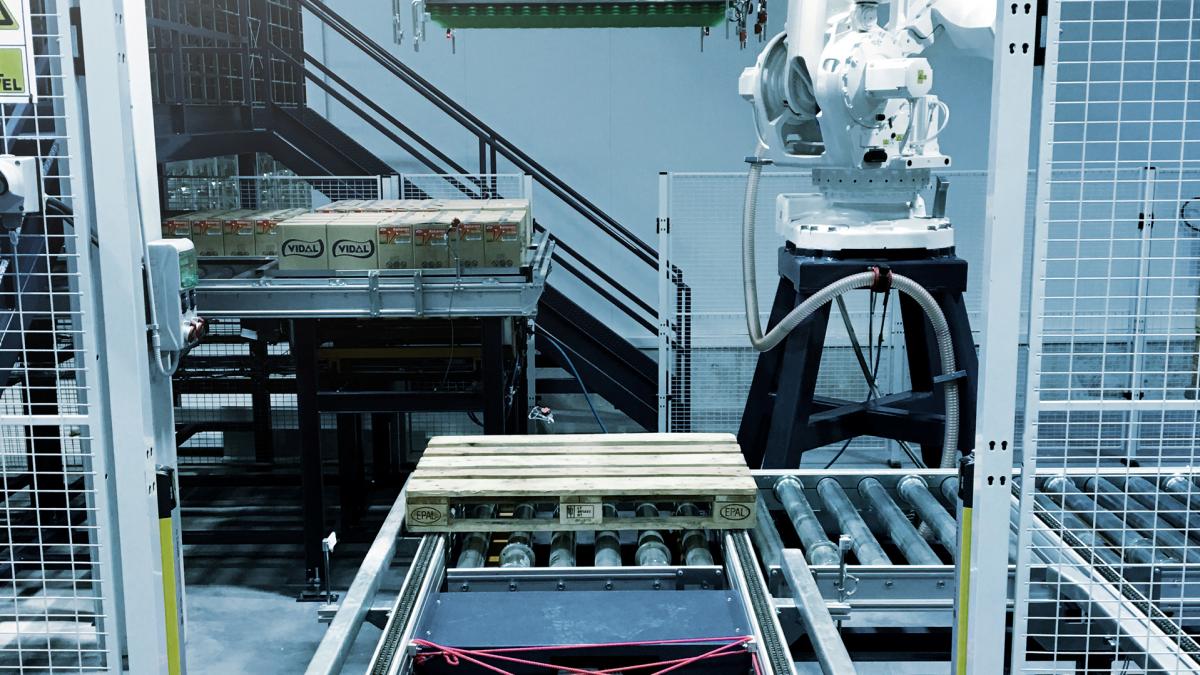

Unit-Load ASRS optimize space for pallet storage

For faster turnover, efficiency and safety in the pallet warehouse

With an automatic pallet warehouse, you make optimum use of your existing storage space and obtain dynamic, fast and efficient intralogistics. These systems help you to react appropriately to increased market requirements such as short order cycles, smaller batch sizes or short delivery times. Automatic pallet warehouses are available as a rack supported building or as a free-standing system within a building, and can be built up to 150 feet high. They are suitable for almost all types of goods, and can also be designed as deep-freeze warehouses. ASRS systems show their strength when a large number of articles have to be stored and handled in limited space. Storage and retrieval machines (S/R machines) such as viapal from viastore, can be utilized with either shuttle forks or other automated systems such as shuttles for deep-lane.

- Optimized storage footprint

- Short throughput times, high availability of goods

- Automated processes that reduce error rates

- Relief of employees from physically strenuous and monotonous activities

Speed and precision are the key factors in the storage and retrieval process. Automated warehouses are efficient, fast, flexible and reliable. They ensure improved inventory management and more efficient order fulfillment as well as short delivery times, require less floor space, have lower energy consumption and enable error-free workflows. Employees are relieved of heavy physical and monotonous work steps and errors are reduced to a minimum. For companies in industry and trade, these factors become a decisive competitive advantage.

We support you in the planning, development and implementation of innovative automatic high-bay warehouses (HBWH), as well as all other material handling automation. As a system integrator, we offer a complete system with storage and retrieval machines (SRM), shuttles, picking systems, conveyor technology, control system (PLC), material flow system (MFS) or material flow computer (MFR) and warehouse management software (WMS). The viadat Warehouse Management System (WMS) and our SAP EWM solutions organize, monitor and control all processes. Therefore, you not only optimize warehouse processes but also reduce the error rate to a minimum.