Tests to guarantee safety of people, machines and facilities

We provide you with a carefree package

As an employer and operator of warehouses, logistics centers, and distribution centers, you are obliged to undergo certain training and tests for the safety of people, machines and facilities. Who better to carry out these tests and instructions than those who know your intralogistics system best? We are your reliable partner, offering you all the necessary training and testing as a complete package. You no longer need to worry about anything. The advantages are obvious: you reduce your overall costs, do not exceed any legal deadlines, save time in scheduling and have only one contact person for your all-round carefree package.

From accident prevention to fire protection, from the step ladder to the electrical system

The legislator stipulates that bearings must be inspected annually in accordance with the accident prevention regulations (UVV). We carry out these UVV inspections in your warehouses and logistics facilities in accordance with the "Employer's Liability for Health and Safety at Work" BGR 234. For your safety.

The storage of goods can be a fire hazard. The hazards can be caused by the stored goods and by the equipment necessary for storage operation. For this reason, fire protection is already in focus during the construction of the warehouse. However, technology, products and load carriers change over time. Is your fire protection still up-to-date? A consistent, constant inspection is urgently required. The best way is through the experts. Best of all by us.

Warehouse operators are obliged to have their racks inspected by a competent person at least every twelve months. viastore specialists are intensively trained and certified shelf inspectors. The annual inspections are carried out during ongoing operations by means of visual checks. All results are recorded and the shelves receive an inspection badge.

Personal protective equipment against falls from a height (PPEgA) must meet high requirements. Every company with high-altitude and unenclosed workplaces is obliged to use these life-saving systems properly and have them inspected at least every twelve months. The viastore service technicians are all trained to be experts for personal protective equipment and decide at a sighting whether the equipment is in perfect condition or has any defects.

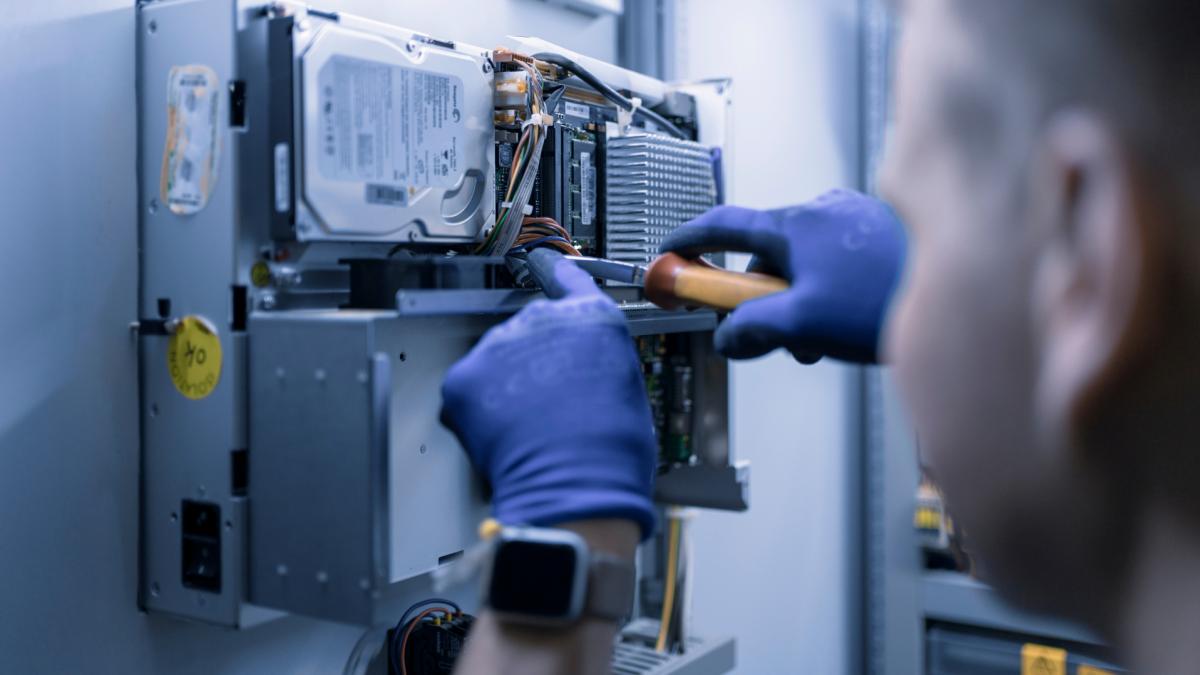

Trade associations and insurance companies exclude their liability if electrical appliances, systems, machines and operating equipment have not been tested in accordance with DGUV V3. viastore will be happy to carry out this test for you and thus protect your employees from possible dangers in everyday work. By documenting the DGUV V3 inspection, you have fulfilled your duty of care and can also provide evidence of this. The inspection period for fixed installations is four years, mobile electrical appliances must be inspected once a year.

Ladders and steps should be checked for proper condition at least every twelve months by an expert. Our employees carry this out professionally, record the results and provide the ladders with an inspection sticker.

Unforeseen signs of wear and tear on machines can cause production downtimes. This results in high costs and time delays. With the help of ultrasonic measuring technology we diagnose damage to the bearings of your machines at an early stage. In addition, we optimize your compressed air system, thereby reducing energy and, as a result, your operating costs. We recommend an annual overall inspection of your system, which viastore will be happy to carry out for you.

We recommend an annual thermographic inspection of the control cabinets and an inspection of the fieldbus system used. This allows quick conclusions to be drawn about the condition of electrical installations and early detection of defective components.

Our experts analyze your system and security risks and identify prevention needs. For maximum service life of your system, highest availability and delivery reliability as well as minimized safety risks.